How Crystal Chandeliers Are Made - Sofary Lighting

Ever wonder how crystal chandeliers are made? It takes a village working together to create those amazing crystal chandeliers. From the idea in the mind, to the design drawings, through the manufacturing process, to the finished product, each step is essential and requires special skills. In this article, we will give you some insights into the crystal chandeliers’ manufacturing process.

STEP 1: Design

Good products always start with design. This is an important part of the chandelier manufacturing process. All SOFARY's crystal chandeliers are meticulously designed by professionals with years of experience in chandelier design. Our professional design team will turn sketches and mock ups into functional lighting concepts. From hand drawing to sophisticated CAD data, the size, sculpting and detailing of each chandelier have been carefully considered by the designer and precisely calculated and tested by the engineer at the micron level to ensure that each product is beautifully shaped and reasonably designed.

One of our advantages is the flexibility in terms of customized design. We offer personalized customization services for your unique needs. With us, SOFARY, you can influence how will your chandelier look.

STEP 2: Manufacture the Base

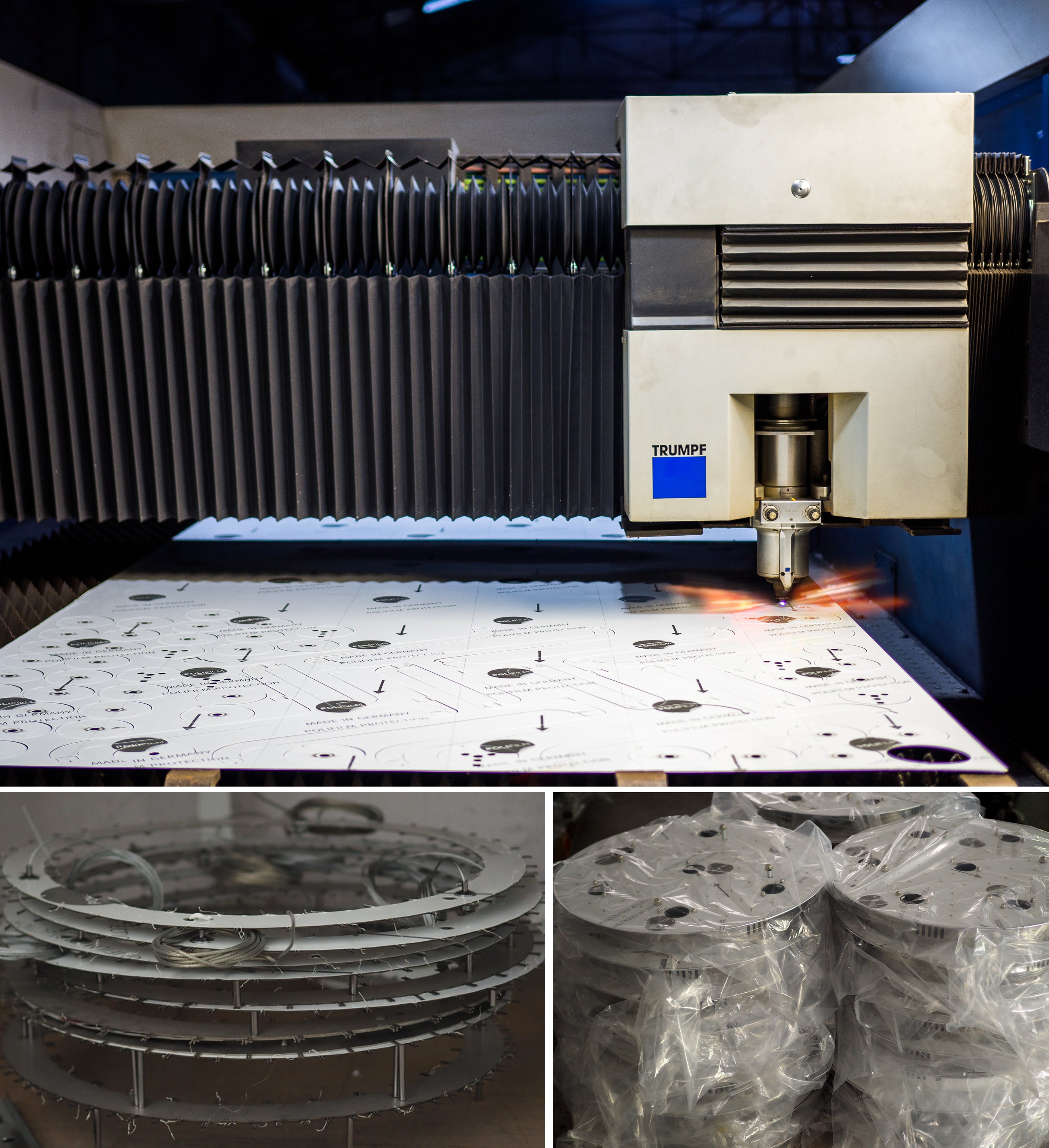

For the quality of a chandelier, the base material is very important. After completing the overall design of the chandelier, we will cut and shape the chandelier base according to the design drawings. The base is made of 1mm high-strength stainless steel and cut into a variety of shapes by a micron-scale laser cutting process.

We use polishing machines to give steel panels the perfect smooth finish. The base of each chandelier is equipped with proper venting holes to ensure good heat dissipation during the long - term use and extend service life.

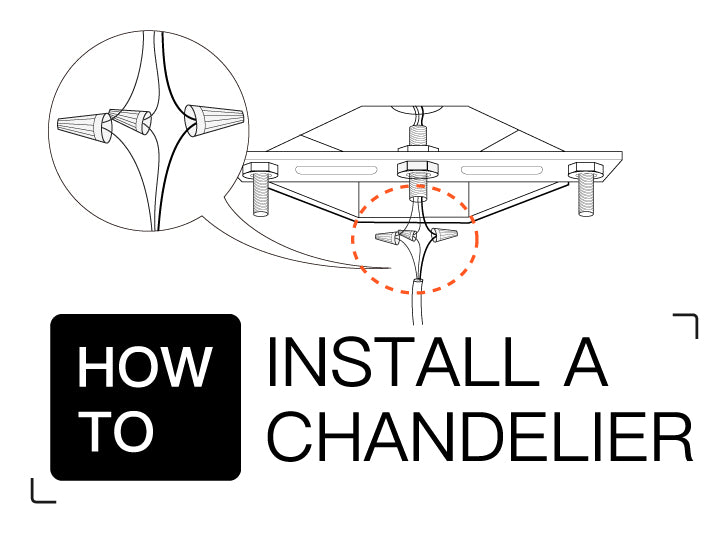

The base of a chandelier provides the electrical connection and mounting. When the base is ready, the chandelier is wired and fitted with its hardware components by skilled technicians. To achieve the desired performance, these processes must be controlled and monitored very carefully.

All the electrical components and wiring in our chandeliers are ETL certified. We use high-quality materials to ensure the stability and safety of the chandelier during its entire lifetime of operation. To make fixtures functional and energy-effective, extensive testing will be performed. Once the light source parts are finished, they go through 15 quality inspections to make sure that they will be security, stability, and reliability while being used.

STEP 3: Chain the Crystals

The crystal is the soul of a crystal chandelier. All our crystal chandeliers are made of high-quality K9 crystal to ensure that our products are shining and pretty with the light of the lamp. K9 crystal is ideal for high-end chandeliers because of its high light transmittance, excellent refraction effect, hardness, texture, as well as its durability.

Because of the wide variety of crystal chandelier styles and their complex shapes, all crystal strings are purely handcrafted. The employees have been rigorously trained before taking up their posts to make sure no mistakes occur during the production process. The production workshop of crystal strings is dust-free. After the craft of crystal strings are finished, they will be put into the sealed bag to ensure the crystal is spotless when it reaches your hands.

Every handmade crystal string contains the SOFARY team's passion for detail, beauty, and creativity.

STEP 4: Packaging

Our dedicated packaging team is responsible for packing the final products. After the production of the crystal string is completed, we will match them with the corresponding chandelier base and hardware accessories, and package them into the special designed foam protected boxes. Before packing and arranging the shipment, quality control team will conduct a final round of quality check on the product to ensure that the chandeliers are in good condition.

Good packaging not only guarantees a safe delivery but represents the very first impression. We use high-density foam to protect the crystal ball at every moment. At the same time, good layout design inside the box also reduce the box size required, which is good for the environment and can reduces the logistics cost. Our goal is always to reduce costs without affecting product quality, which is one of our low-cost management concepts.

The outer packaging of the foam box adopts double-layer ultra-thick corrugated paper. This high-strength corrugated paper can minimize damage during shipping and ensure that our products reach your hands in good condition.

STEP 5: Shipping

After the completion of packaging, our warehouse management staff will label and organize the products properly so that they can be delivered to the shipping agent as quick as possible to ensure that they can reach our customers as soon as possible.

The above are the production processes of our crystal chandelier products. We will continue to devote our passion for quality to every aspect of products from SOFARY, strive for excellence, and ensure total customer satisfaction.

Thanks for reading this far, hope that you learned something from it. Ready to find a crystal chandelier for you home? Start here and feel free to reach us at support@sofary.com if you have any question.